1.

2.

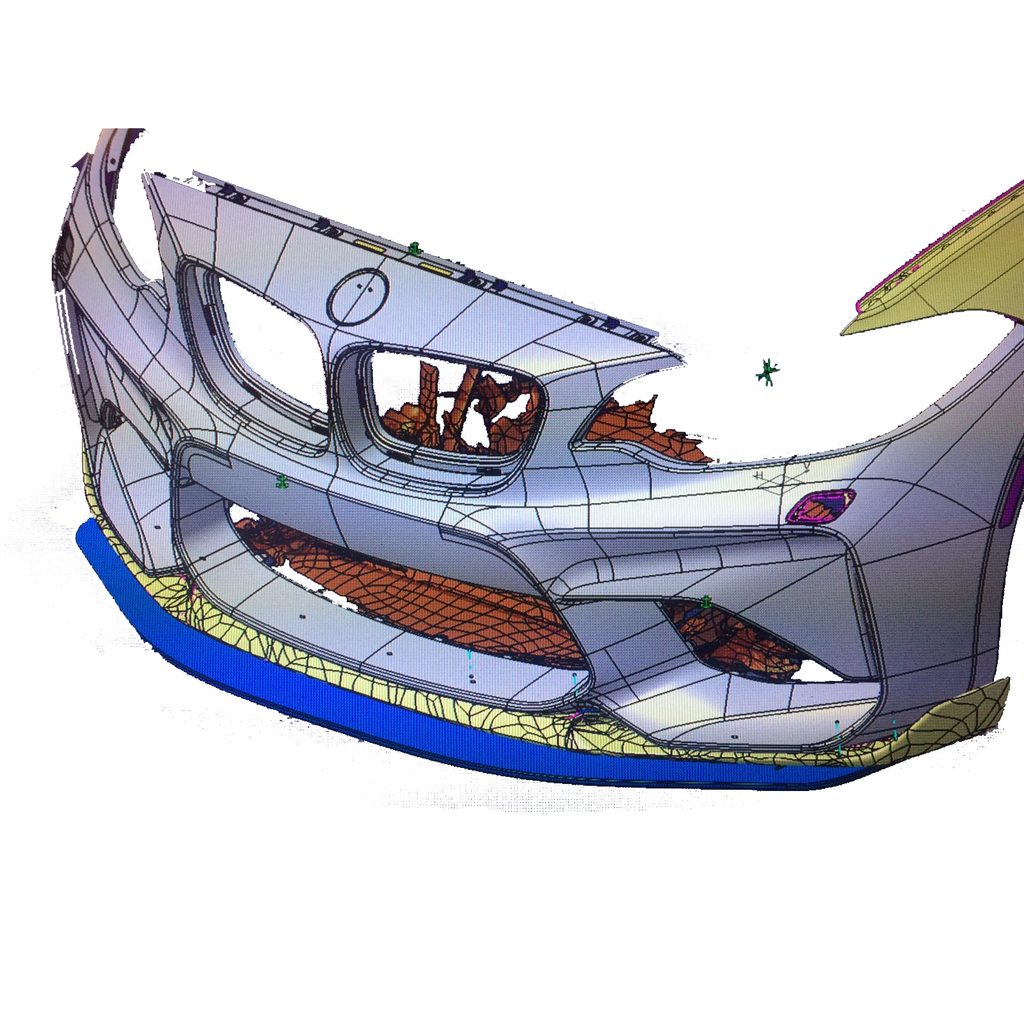

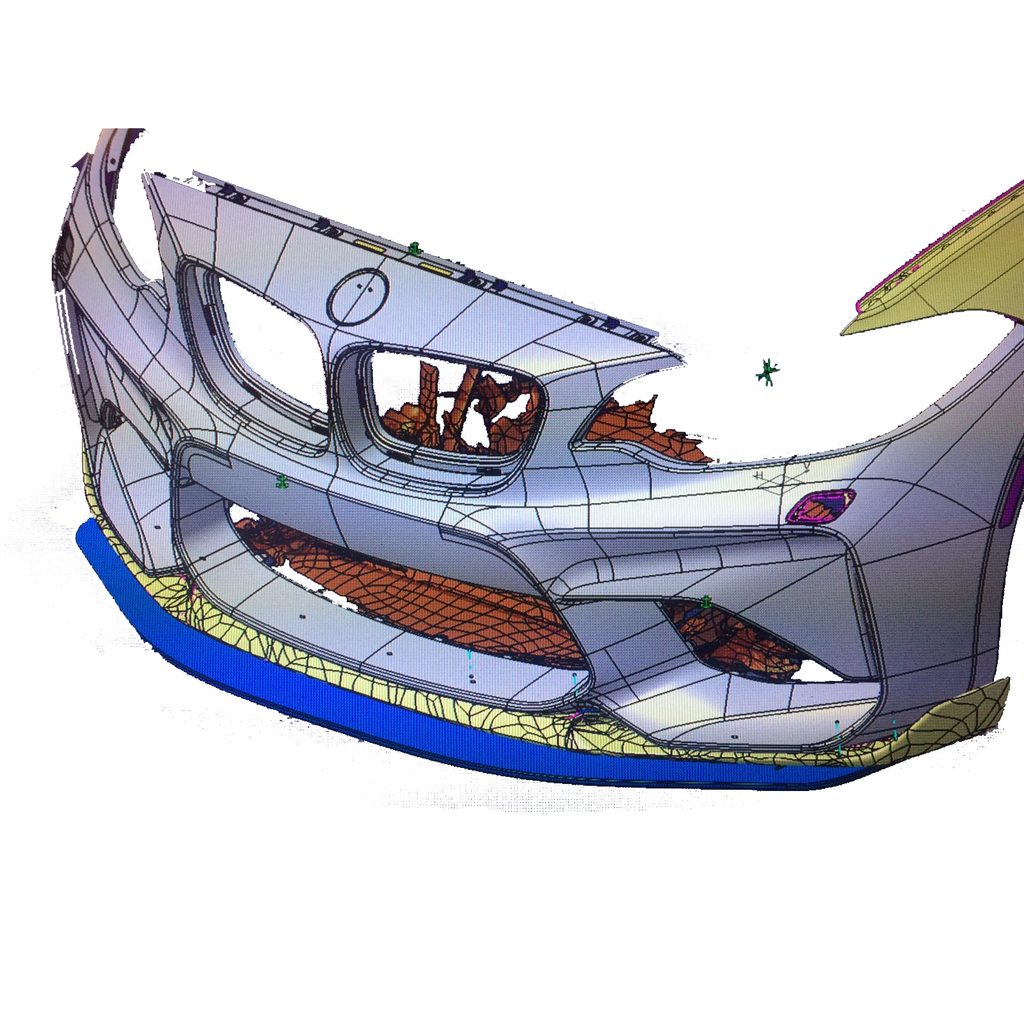

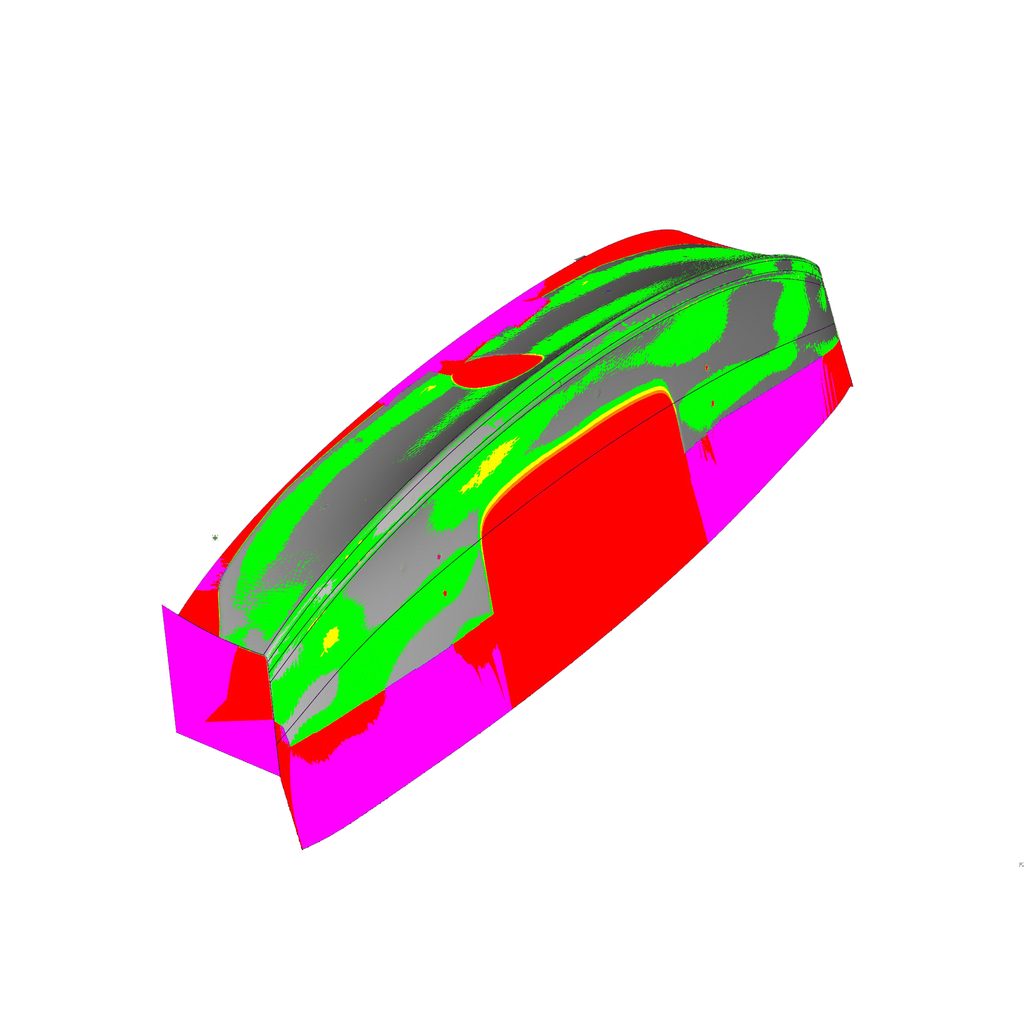

If you don't have any CAD data for us or you want us to create them, we need a scan (digitization) of your component. We are happy to offer you that. From small components to complete vehicles.

3.

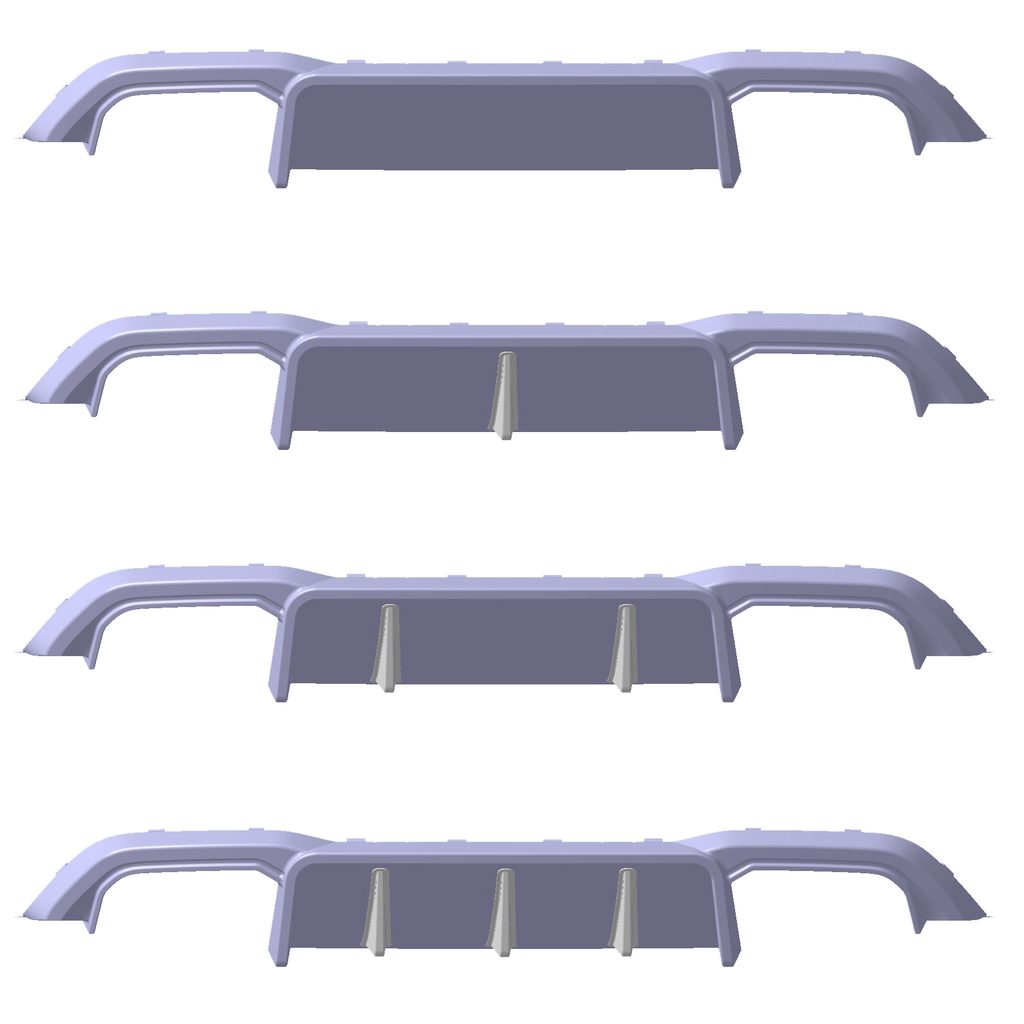

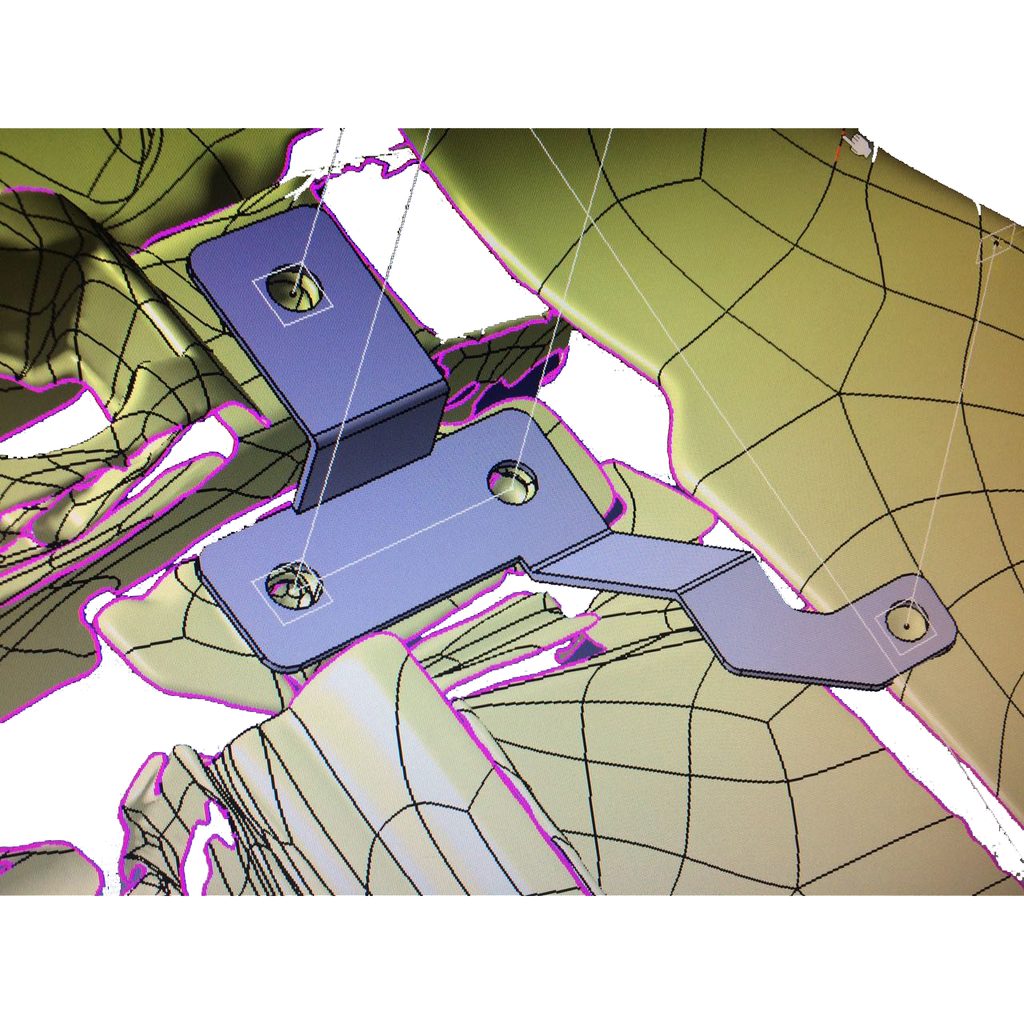

Model and mold construction in all common processes such as infusion, prepreg, milled epoxy resin or aluminum.

4.

Model and mold construction in all common processes such as infusion, prepreg, milled epoxy resin or aluminum.

5.

Autoclave Prepreg

The advantages of manufacturing in an autoclave are obvious.

Very high quality, very light and yet highly stable components for a wide variety of applications.

Vacuum Infusion

The advantages of manufacturing using the vacuum infusion process come into their own with smaller quantities.

6.

7.

We are happy to carry out material tests for your products. Our products are repeatedly subjected to various tests (e.g. xenon tests, condensation water tests, chemical resistance tests, stone chipping, splinter behavior and others).

8.

We are happy to help you with the preparation of parts certificates or ABEs (General Operating Permit).

9.